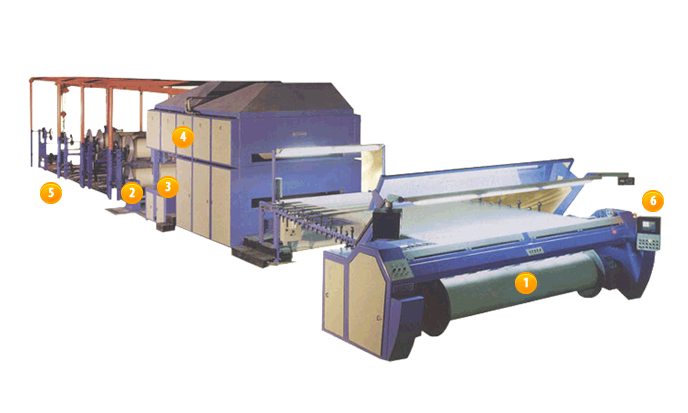

Sizing Machines ( Slasher )

1 ) HIGH PERFORMANCE HEAD-STOCK

- Two way beam winding

- Rubber covered delivery cylinder and hard chromium plated press roll.

- Uniform warp density and constant tension.

- Upper press system, sypported by pneumatic piston.

- Electronic rotational speed control with varying beam diameter.

- Accordion comb with double motor and oscillator (for distance adjustable right/left motion) system.

2 ) SECTIONAL WARP BEAM UNWINDING UNIT

- Designed for sizing of sectional warp beams,

- PLC controlled pneumatic brake system connected to ratio valve,

- Automatic yarn tension adjustment for variable diameter.

3 ) SIZE BOX

- Overflow system, for economical size consumption.

- Metal jacket steam heating for homogeneous heat distribution.

- Rubber covered immersion and upper squeeze cylinders, hard chromium plated lower squeeze cylinders.

- Automatic squeeze cylinders lift-up in case of emergency stops / shut downs.

- Ratio valve controlled automatic squeeze pressure adjustment as per machine speed.

- Adjustable size level by hinged barrier.

- Loadcell supported yarn tension controls at inlet and outlet of size box.

- Seperate control panel for pneumatic pressure and size transfer.

- Adjustable squeeze pressure as per yarn type and count

- Homogeneous squeeze pressure distribution by special internal structure of squeeze cylinders.

- Economical sizing cost by filtered recirculation system.

- Size box monitoring by close loop camera system.

4 ) DRYING UNIT

- Teflon coated / stainless steel drying cylinders.

- Individual heat control for each section.

- Automatic instant steam evacuation.

- Stainless steel aspirator hood.

- High speed suction system with radial fan.

- Yarn tension compensation at inlet and outlet of drying unit.

5 ) BEAM CREEL

- PLC controlled band brakes actuated by pneumatic pistons with ratio valve.

- The yarn tension can be dajusted automatically and constant tension is provided throghout the whole diameter range of the warp beams.

- Easy loading / unloading of warp beam by bearing supported wheel system for each beam.

6 ) OPERATOR PANEL

- Touchmatic color graphic screen.

- 500 recipe memory.

- Centrally controlled operation,

- Faults and error memory.

We provide quality and reliable service to our valued customers.

Support: kucuker@kucukermakina.com

Copyrights © 2017 All Rights Reserved.