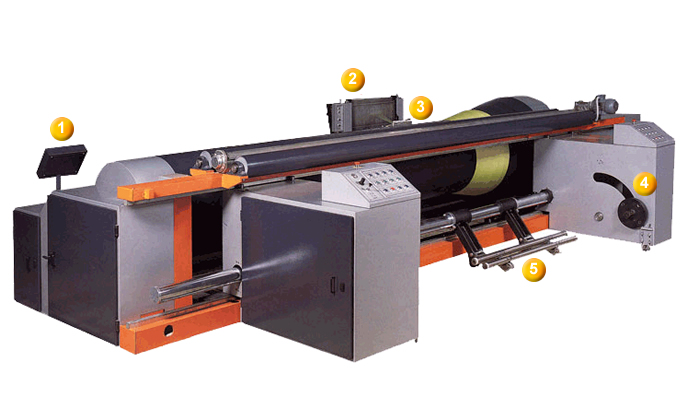

Sectional Warping Machines

1) PLC / OPERATOR PANEL

- Touch-matic, color graphic, operator friendly screen,

- Automatic process data values calculation, as per input warp values,

- Instant procees info transfer during operation,

- Error and fault memory,

- 500 recipe memory,

- Saved recipe can be recalled and activated instantly,

- Operation faults can be tracked from recipe memory.

2) LEASING COMB

- Motor driven positioning in leasing,

- Automatic open/close motion while warping,

- Long life guarantee of comb with,automatic vertical motion while warping.

3) SUPPORT

- Location check by laser sensors,

- Automatic band start point detector,

- V-comb supported by pneumatic pistons,

- Uniform winding density with diameter control and constant rotational speed,

- Two seperate servo motors to position support in two demension,

- Automatic tension check / compensation system during warping,

- Homogeneous warp tension and density and adjustable pneumatic press system.

4) BEAM WINDING UNIT

- Hydraulic piston driven, circular beam loading / unloading system,

- Servo motor driven, automatic warp tracking system depending on warp density,

- Independent, magnetic-braked and ac motor driven beam winding motion,

- Automatic stops for broken ends and saved memory,

- Independent, ac motor driven distance adjustment,

- Warp efficiency at high speed while beaming,

- Constant tension control while beaming with pneumatic piston supported calipper system.

5) BEAM PRESS UNIT

- The device consist of two parallel cylinders with displaced centers of gravity, the device is set such that one end of each cylinder extends up to one flange of the beam,

- Up / down movement supported by pneumatic pistons,

- Warp surface smoothness with beam press unit.

We provide quality and reliable service to our valued customers.

Support: kucuker@kucukermakina.com

Copyrights © 2017 All Rights Reserved.